Development of

Diffusion Tactile Display and

Research on Applications

1. Objectives

The proposed project includes establishing a method of commercially producing a low-cost tactile display system of reliable quality for the blind and visually impaired, development of contents to be offered and implementation of trial operation. By developing applications concurrently with the device, we aim to create a value-added tool that will assist blind or visually impaired persons in comprehensive aspects of daily life.

A continuous information provision system will be created to ensure that information on system uses is made public.

2. Description of R&D Project

(1) Current problems, needs of potential users,

purpose of this R&D project

Various studies have been conducted on methods of providing information to people with visual impairments, with focus on Braille, stereo copying and audio response. Remarkable progress has been made in these methods, thanks to the use of computers. However, we now face the urgent problem that there is no low-priced, high-quality display unit. The devices developed thus far are all too expensive for organizations for the blind and visually impaired, or for such individuals, to buy and use. With growing awareness of the importance of shape recognition in the education of children with visual impairments, there is a pressing need to develop a less costly display system.

Stereo copying machines and other products designed to provide sensory substitution also have disadvantages in terms of size and operating cost, and are not in everyday use by people with visual impairments. As a result, it is difficult for such persons to benefit from the diffusion of personal computers and the widening of the Internet.

In this R&D project, we have been working to develop and commercialize a raised representation display system for blind and visually impaired persons. To realize low cost and high durability, we employed a simple mechanism in which several solenoids scan image and other data mechanically. We hope that we can successfully commercialize a low-priced display system, which would be a boon to people with visual impairments. (The display system will be connected to a computer to provide information to blind and visually impaired persons.)

(2) Differences from existing products

[Existing products]

Stereo copying machine:

Images are printed onto special paper to produce raised graphics. Portable models are not available. The biggest difference is that refreshable display is not an objective in the development of stereo copying machines.

Optacon:

A reading device that conveys scanned graphic images to the fingertips through vibrating pins. Since skill is required, it is difficult for general people with visual impairments to use this equipment.

Braille Pin Display:

With 4,072 cells, the device is sufficiently capable of presenting graphics. However, since each cell has an individual actuator the price is high, making it less affordable to blind and visually impaired individuals.

Dot View:

With 768 cells, the device is relatively inexpensive. However, lower price was realized by decreasing resolution, which means lower information-carrying capacity. There is a limit to further cost reduction, since the device employs the individual drive system.

Our tactile display system currently under development has a simple mechanism in which 3,072 cells are mechanically driven according to scanned data, with the view to realizing a selling price of 2,500 to 3,000 euros. (The target price range is subject to change due to exchange rate fluctuations.)

The drive unit of a simple structure with a small number of components is the largest point of difference from conventional displays for raised representation, and will enable us to offer this display system at low prices.

We have developed an initial prototype model and have begun evaluation testing in preparation for commercial production. To meet market needs, it is necessary to reduce production costs and offer a wide variety of applications.

(3) Device Outline

Performance/functions (Description of R&D project in terms of technologies or materials)

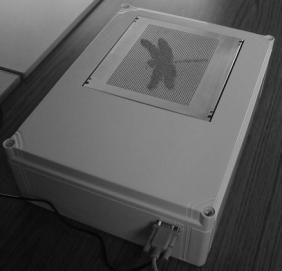

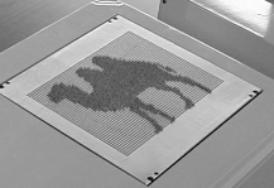

With a resolution of 3,072 (48 by 64) pixels, the display unit processes and outputs visual data on the PC screen to rows of cells that can be raised and lowered, enabling blind or visually impaired users to feel the image by touching a raised version of the image.

‚ Target users, environment and applications

Target users will be people with visual impairments (particularly those with total blindness or extremely weak eyesight). Our desired goal is to create a display system that can be used in all aspects of daily life by blind or visually impaired individuals, as one of their personal belongings.

Example

applications

a. Tactile reading of text and image

data displayed on Internet web pages using PC

Computer-generated

rendering Showing

of dragonfly by present model

Showing of maple leaf illustration

by present model

Showing of camel by present model

Showing of camel by present model

![]() Showing of Chinese character

Showing of Chinese character

b. Detection and recognition of textured paving blocks around the

user on the street

![]()

c. Educational materials for use by blind and

visually impaired children in learning characters or how to read (feel) graphic

information

ƒ Benefits

This system enables the blind and visually impaired to read characters and graphic data, a feat considered impossible in the past. On the street, the tactile display will convey information on surroundings (landscape, traffic condition, etc.) to the userfs fingertips. These functions will not only improve the quality of life of blind and visually impaired persons, it will also be of great help to them in leading self-sustained lives.

„ Other

Various organizations have studied tactile graphic displays thus far, but have failed to market such products. We will make our tactile display system marketable and practical by employing new technologies that realize both high resolution and low cost, and by producing the products in large quantities.

In addition, we

will develop and compile data on application software in collaboration with the

Japan Federation of the Blind (Chairman Yoshihiko SASAGAWA), and will implement

trial operation to create a value-added environment for using the proposed

display system.

3. Prospect for Commercialization

(1) Prospect for commercialization

It is possible to market a display system of reliable quality by employing the injection molding, pressing or other mass-production method for the main structure of the present working model.

To establish a more convenient method of providing information, we will develop data on shape information for blind and visually impaired persons, and will conduct evaluation testing.

(2) Commercialization plan and procedures

We will study manufacturing methods for a production model, and will manufacture pilot units to be tested for reliability and durability.

Evaluation of appropriateness of adopting the electrochemical machining and injection molding methods, using a durability testing machine

‚ Mechanism design and control board development suitable for the machining and processing methods to be employed

ƒ Experimental manufacture of production model

„ Commencement of sale

4. Related R&D Activities and Implementation

Plan

|

Activity |

|

|

Survey of applications |

Survey of applications and needs using prototype model |

|

Study of methods of conveying information based on the sense of touch, and development of sample data |

Study of methods of conveying map information Study of the multi-modal information provision method, which is combined with voice message, and development of sample data |

|

Study of applications as educational tool |

Survey of educational materials for conveying shape information Development of tactile educational material samples |

|

Software design |

Design of firmware inside the device |

|

Electrical hardware design |

Design of control circuit Design modification based on evaluation results |

|

PC software design |

Development of software suitable for applications |

|

Survey of manufacturing methods for commercial production |

Survey of perforated plate manufacturing methods |

|

Survey of tactile pin manufacturing methods |

|

|

Trial manufacture using processing methods for commercial production |

Trial manufacture of components using processing method suitable for commercial production |

|

Mechanism design for commercial production |

Design of a mechanism suitable for commercial production |

|

Trial manufacture of commercial production machines |

Trial manufacture of commercial production machines |

|

Manufacture of production model |

Manufacture of 5 units of production model after manufacture of 5 pilot units for demonstration experiments |

|

Manufacture of reliability and durability testing equipment |

Manufacture of equipment used for reliability and durability evaluation |

|

Reliability and durability tests |

Testing production model reliability and durability |

|

Modification of mechanism design for commercial production |

Design-related actions to cope with quality problems at stage of commercial production |

|

Demonstration experiments |

Study of methods for optimizing demonstration experiments by blind and visually impaired users |

|

Software adjustment |

Software adjustment |

|

Sale |

Distribution of contents and sale |

5. R&D Activity

Results from 2000 to April 2004

We manufactured five pilot units of the low-cost tactile display system. These units were subjected to numerous evaluation tests by providing a wide variety of content to blind and visually impaired users. We confirmed that tactile graphic representations would open up great possibilities.

With successful development of an automatic assembly unit and durability testing equipment, we resolved the conventional problems of ghigh manufacturing process cost and unstable quality due to manual assembly method,h thereby realizing a commercial production system at low cost.

(1) Study of information provision methods

To improve the work efficiency of converting a huge amount of existing data, we developed software that automatically converts PC Clipboard images.

(2) Design of electrical hardware

We developed a dedicated CPU board for control and carried out operation and durability testing.

(3) Design of computer software

We succeeded in developing software that converts images on the Windows Clipboard to raised graphics through communication with H8-CPU.

(4) Survey of commercial production methods and trial manufacture

By developing etched plate laminated pad and shifting from the conventional cutting method, we achieved a 90% reduction in the manufacturing costs of perforated components.

Initially, the 3,072 pins per unit were assembled by hand. However, by completing trial manufacture of the automatic assembly machine, we succeeded in automating the work.

(5) Manufacture of pilot units for demonstration experiments

In December 2003, we completed manufacture of five pilot units, which are currently in use for durability testing and study of applications.

(6) Survey of applications and needs using pilot units

We conducted surveys at a prefectural school for the blind and support facilities for the blind and visually impaired. By making public the prototype model, we received requests from many people with visual impairments and reflect those requests in developing a production model.

6. Future Plan and Tasks

Using the five pilot units, we will perform the following tasks over the next year.

(1) Improvement of hardware performance and development of content, based on ongoing surveys of requests from blind and visually impaired persons

(2) Continuation of durability testing

(3) Establishment of commercial production system

We will develop and manufacture a first market model by March 2005 and create a system that enables us to offer the tactile display unit at low prices to blind and visually impaired people in Japan and abroad, as a tool useful in their everyday life and education.

Attached photographs

A. Appearance of unit: Showing Chinese characters and alphabets

B. Example image conversion: Mona Lisa

C. Example image conversion: Camel

D. Example characters conversion: LOVE

E. Example of conversion of images shot from a camera: A child

F. Example of map image conversion: Map of Japan

G. Automatic pin assembly machine